If you need a new conveyor system, one kind you should consider is the inclined conveyor belt. When you look past its unusual construction, this small but mighty belt has a lot to offer. Here are four big benefits of inclined conveyor belts you should know about.

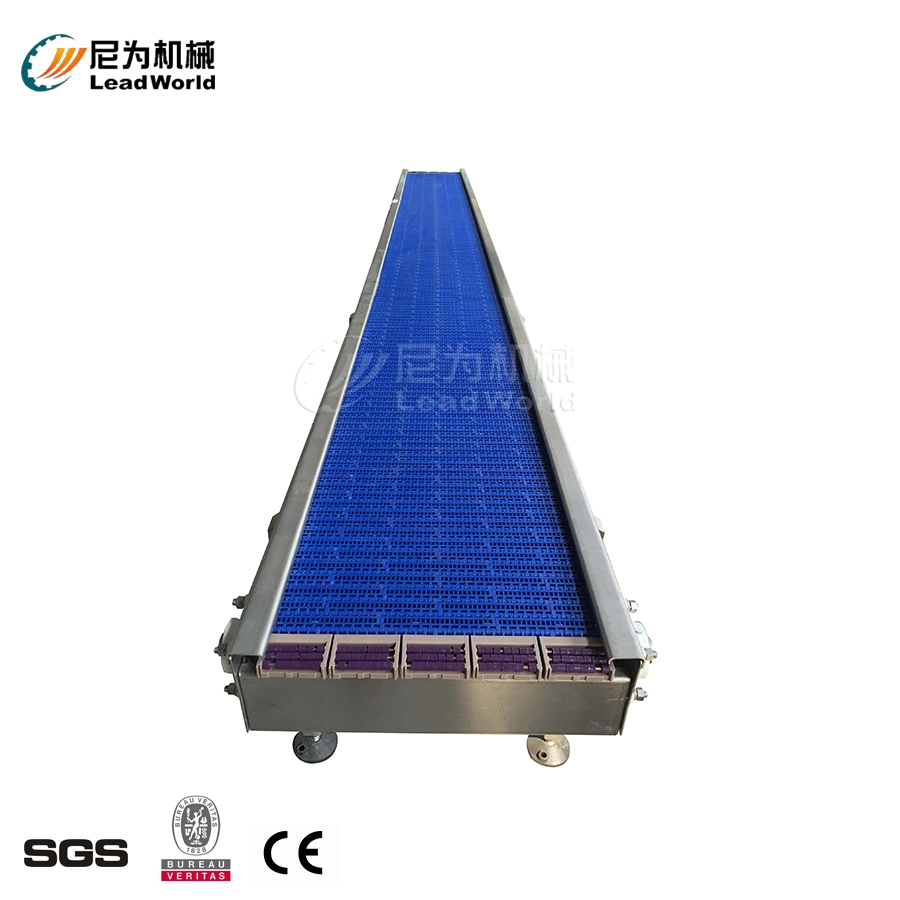

You may have already guessed from the name, but inclined conveyor belts are conveyors that operate at an 18–90-degree angle. There are two kinds of inclined conveyor belts: standard incline and steep incline. Steep incline conveyors operate at a steeper angle than standard inclined conveyors.

There are several benefits to using inclined conveyor belts for your facility.

Inclined conveyor belts have remarkably small footprints, which make them ideal choices if your facility is short on room.

With an inclined conveyor belt, you can easily move materials up and down from various levels. If your business utilizes platforms, this eliminates the need for workers to carry materials up and down by hand, thus reducing labor and the risk for injuries.

By limiting movement of materials to a smooth, steady L- or S-shape path, inclined conveyor belts prevent abrasion and lengthen belt life.

You can customize inclined conveyor belts with barriers and grips that hold materials firmly in place. These features, paired with the precise angle this kind of belt uses, dramatically reduces the risk of material loss and damage.

Inclined conveyor belts are ideal for facilities that are short on space or ones that are multi-level, but they provide other perks that even massive, one-level facilities can take advantage of. If you want to maximize space, reduce labor costs, decrease material and belt wear, and make your facility safer, give inclined belts a try—no matter your needs, they can help improve productivity and your bottom line.